Car brakes are one of the most important performance upgrades you can make to a car, not just from a safety point of view, but also gaining the advantage over your competitors. Your car's brake performance must match it's power and handling for the car to be competitive- especially on corner entry and overtaking. There is no point being the fastest car on the road or track and when you need the brakes to stop, you can't make the turn.

Normally performance brake upgrades would come in different stages, including uprating the brake pad material and using larger ventilated two-piece disc (rotor), also steel braided brake lines, larger callipers and different brake pad materials. Theses are a few of the options available as braking systems are a integral part of a good performance package and there a lot of effective products out there.

A brake disc can be made of a number of different materials including castor iron ceramics and composites (including carbon, kevlar and silica). These material usage is in an attempt to reduce brake fade, increase heat dissipation and the cars stopping power. While not all materials will be safe or effective for the road due to usage criteria, careful selection should be taken.

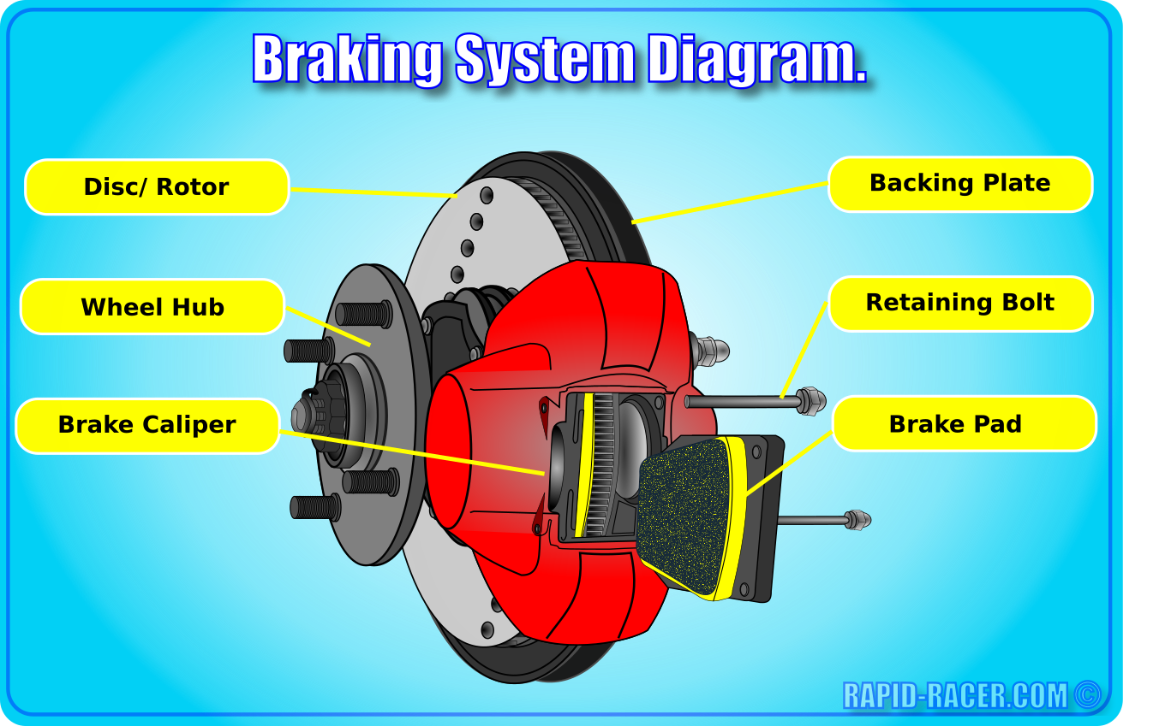

How Car Brakes Work

Your press your foot on the brake pedal and the car stops, hopefully right? Well lets dig a little deeper and find out what is happening.

The disc/ rotos brakes which causes the wheels to stop rotating are a device mounted normally on each wheel axle and we will only cover this type rather then drum brakes (low performance potential and considered primitive technology). It is well worth rejecting this type of set up for the rear of the car if they are present- it is best to seek donor cars or upgrade the whole system for a pure disc/ rotor set up.

The brake disc is connected directly to the wheel or axle and friction material called brake pads are mounted on a brake calliper and activated via the a foot pedal and brake pistons. These can be forced mechanically, hydraulically, pneumatically or electromagnetically, against both sides of the disc, converting kinetic energy into heat. The friction that this causes between the disc and pad, slows or stops the wheels rotation and this process generates high brake temperatures, in many high performance applications you will see the disc glowing amber or red hot. Brake fade occurs when too much heat builds up and stops the friction from the given materials interacting (making contact), decreases its effectiveness.

Normally a standard braking system will consist of a brake pedal which is connected to a master cylinder containing brake fluid, this in turn is connected to the slave cylinder which has a piston that pushes the brake pads against the discs on activating of the brake pedal.

This action of effectively clamping the materials together (brake pads and discs), is what converts the kinetic energy of the moving wheels into mostly heat and effectively slows the rotation of the wheel down.

The number of pistons and the material used in both the brake pads and discs, are where real performance gains can be achieved over OEM products. As they are designed with out maximum braking efficiency in mind, also other budget restraints to the manufacturing objectives.

In high performance car models this has been engineered into the equation, but like most things which are sold; everything has a mark up and budget. By using a combination of different materials you can effective increase braking performance significantly. Especially on less expensive, mass produced car models not intended for motor sport use.

Even the shape of the brake disc has an effect on the performance of the braking system and lots of research has been undertaken with drilled, crossed slotted and even a combination of both to effectively increase breaking performance and more importantly dissipate heat- we cover this in more depth in Car Brake Upgrades.

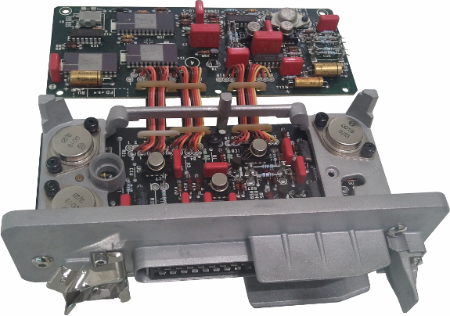

ABS Braking

Anti Braking System Brakes ( known as ABS) are a device used to stop the brakes locking but under extreme conditions and follow the principles of the traction circle. Once all available grip for braking is exceeded ( tyres/ tires max grip levels), the wheel will lock up and begin to skid- which reduces braking efficiency by up to 30%. In the old days we could use Cadence Braking to overcome this, ABS braking is a driver aid to effective release some of the braking force to release more grip for braking, without lifting off the brake pedal.

When ABS is activated through predetermined settings, sensors located in the wheels ,will stop the tyres/ tires from locking up by manipulating brake pressure, also the amount of turning percentage required is modulated with steering wheel inputs- again simulating the Cadence braking technique. If you have more steering wheel input for turning- you get less braking force. So in all this is a pretty useful safety edition for everyday driving and no doubt has saved many lives and avoided accidents.

While ABS braking is a huge safety net for everyday driving, it does not hold the ultimate in braking possibilities due to the nature of the sensor settings and limits of tyre adhesion, combined with different weather and track conditions. If a ABS sensor specification is set up for the manufacture with standard tyres/ tires, this could not possible take into consideration dynamic track environment, weather conditions and the characteristics of racing tyres- with wear rates and heat cycles etc.

Ultimately this is what makes the difference with racing drivers and road users- the small little performance advantages which can be had with the right skill levels on a circuit as opposed to the safety of a road car specification. Having the freedom and safety of a track environment can help hone driver skills levels and let you become familiar with the limits of the car. This is when ABS can not compete with the knowledge and skill of the human mind, with experience of his car and racing environment- who knows in the future these braking systems may ever increase in their capacities.

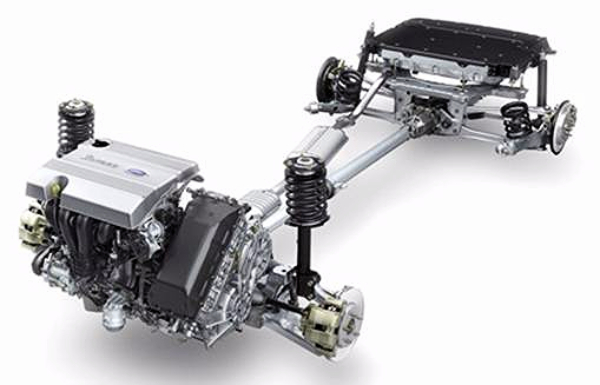

Regenerative Braking

In the world of cars, the faster you want to accelerate; the more power is required to overcome the air resistance and drag of a given body design. Regenerative braking is a way to save and store some of these energies used to get the car up to speed, when braking and utilise otherwise wasted energy. Ready to be used to aid in acceleration again.

In a conventional or electric car, torque is required to move the wheels and frictional losses through the drivechain and causes inefficiency in that power being transmitted. The same losses occur when you apply the brakes and this energy is converted from kinetic energy (movement) to heat, in an aid to slow down the car. It is a lose-lose situation in terms of energy loses,and is essentially a inefficient technological set up.

Regenerative braking can help to keep these losses to a minimum and can even help to increase fuel efficiency. With greener and more effective braking systems being adopted, the future of the car doesn't look so bleak.

We now know Regenerative Braking can be used to harness the wasted energies in a traditional braking set up, this energy can also be stored for use later on in batteries or capacitors.

This can recharge electric cars while on the move to further boost their driving range, but can also now be adaptive to boost petrol car green credentials and even act as a performance boost for sporting models.

There are a number of different ways of doing this, but the most common is where electric motors are used as generators to produce the electricity under braking loads. Fundamentally reversing the power delivery process, to power generation. Pneumatics, hydraulics or rotating flywheels can also be used. Electric trams have for example being using this technology for some time and is relatively a new concept for automobiles.

While this sounds like it should be a win-win situation, currently we do have some issues which prevent a pure Regenerative Braking System.

The reason that traditional braking systems have not been replaced with regenerative braking, are as follows:

Regenerative braking losses at lower speeds are reduced and less effective in harvesting, also it can not bring the car to a total halt or be used effective for locking the rotors totally (used in hill starts for example).

In FF (front wheel drive) or FR (Front rear wheel drive) driveline configurations, four wheeled braking is needed in wet or slippery conditions to maximise stability. In a 2 wheel electric drive set ups, this will not be possible on the other wheels which are not driven.

Under emergency braking conditions, it is required to have maximum braking capacity all the way through the speed range. As regenerative braking is less efficient at lower speeds, this will be unacceptable for everyday driving. Also in some cars (non- performance models), the maximum forces of their acceleration capacities are a lot less then their braking capacities. From a production point of view, they would need larger capacitors just for braking then is required to provide drive. Ultimately making them more expensive.

We have seen a more wide application in these technologies in the automotive world with cars like the Toyota Pruis. I suppose this is just the start for these Innovations in the General Automotive world and even Motorsports. Take F1 KERS (Kinetic Energy Recovery System) for example, introduced the reuse of some of this wasted losses and further increase the performance.

Brake Bias

Brake bias is the percentage of front to rear braking capacity of a car and is normally set up as per manufactures specifications, while this is no doubt set up for maximum safety, when we want to extract more performance this could be another area to review. A brake bias, which is normally fitted with in hands reach of the driver- is a device which can be operated on the fly to change the braking power of the front versus back relationship.

A car's level of grip and it's attitude under weight transfer from heavy deceleration affects the brake balance of the car. As you increase the performance of a car, you may need to adjust brake balance to maximise braking effort. There are many reasons why the balance may no longer be optimum from standard, this could for example be following performance upgrades which might affect the weight of the car, different tyre/ tire performance levels or even fuel load during a race.

Adjusting the brake balance during these situations can help re-balance the understeer and oversteer equilibrium to maximise performance upgrades.

Due to braking efficiency being this magic spot and dynamic in nature due to weather conditions, tyre wear rates and even fuel loads throughout a race can all have their impact on the desired setting. Having the ability to maximise and stabilise braking efficiency during a race could be key to winning and can make an impact on lap times. By controlling the relative distribution of hydraulic pressure between the front and rear brakes, you can affect tyre/ tire lock-up both front and rear.

It is important to make sure all brakes are not under utilise as this will have a negative effect on the overall braking capacity and potentially even affect tyre/ tire wear rates and heat management- especially critical for any endurance racing.

Care must be taken to get the desired handling characteristics. The front brakes do most of the work in production braking systems and a 60:40 front bias is the norm, so only small adjustments should be make to try and get all four wheels locking up at the same time. Which is the ultimate aim.

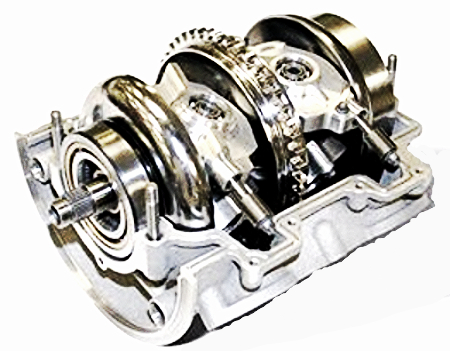

Kinetic Energy Recovery System (KERS)

Kinetic Energy Recovery System (or KERS) was introduced in the F1 2009 Season. KERS effectively is a way of harnessing the deceleration and braking forces of slowing the car, normally wasted in traditional braking set ups. Transforming it into energy, which can be stored in batteries or a flywheels for short burst of acceleration power later on. It is a form of Regenerative braking as seen in many other types of vehicles over the years.

Although restricted initially to around 80 BHP in the 2009 F1 season, the FIA in a aid to make F1 a greener and more exciting sport, will continue to increase the maximum limits in the future, especially as small capacity engines are introduced.

This may not be a Brake Upgrade you will be able to get your hands on just now, to retro fit to older cars, but other types of regenerative braking is increasingly used in new Electric and Hybrid cars to boost their driving range. The F1 KERS technology was developed for the 2009 F1 season to boost acceleration performance, by utilising wasted kinetic and friction energies in traditional braking. While other regenerative braking is used for increased efficiency.